Your Custom Text Here

The beginning

Beginning of the teardown, making sure to label all the parts for eventual reassembly.

Engine out

Dropped the engine out of the bay and removed the cylinder heads.

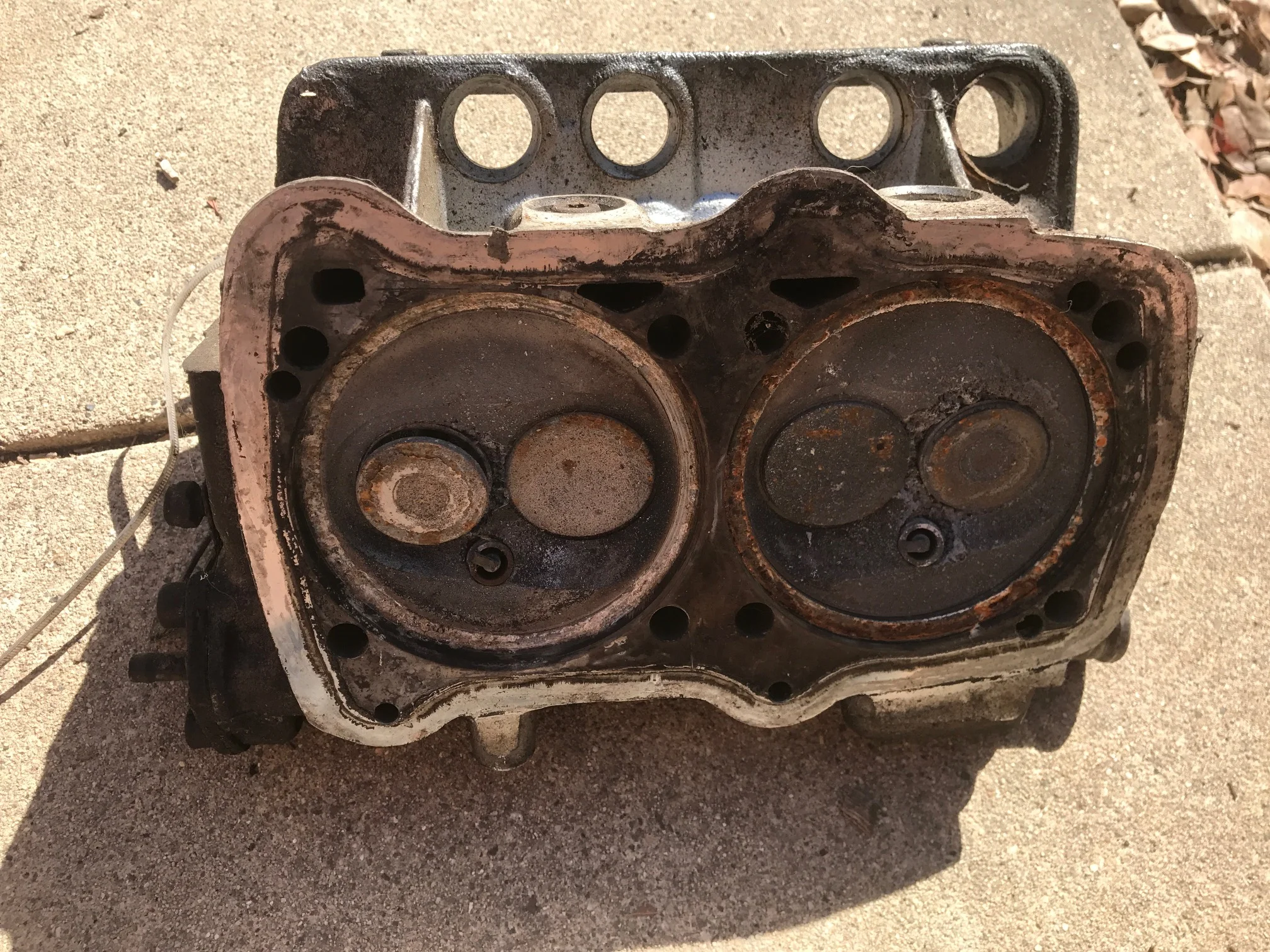

Damaged heads

The cylinder heads were pitted and damaged beyond repair. You can tell the exhaust valve on the far left is stuck open.

Engine Block

Passenger-side of the engine block all cleaned up.

Engine Block

Driver-side of the engine block.

Shafts Installed

Got the crankshaft polished and cleaned before installing it. The camshaft was good enough to reuse. Bearings for both shafts were replaced. The crankshaft bearings were surprisingly difficult to source because VW had two standard outside diameter bearing sizes. Unfortunately, shops today just sell “standard” bearings, not realizing that standard doesn’t have a single definition.

Test fitting larger bore cylinders and pistons

The PVC pipe is a homebrewed way to keep the cylinder in place while rotating the crankshaft. At bottom dead center there was interference between the piston and engine block, requiring clearancing. The larger bore resulted in ~10% more horsepower.

Before

The engine block marked where it needed to be clearanced. This was tough to mark - I had to reach through the other engine block openings with the piston at bottom dead center.

After

The material removed to make room for the piston skirt. This was repeated for each cylinder.

Engine assembled

Engine block, cylinder heads, and flywheel all torqued to spec.

Engine installed

The engine installs with 4 bolts to the transmission and 4 bolts to the chassis. Then it’s time to hook up all the hoses and wiring.

Engine Running

The first sounds of the newly built engine.